- Enhance the characteristics of composite PVDF hollow fiber membrane:

- High strength: The reinforced composite PVDF hollow fiber membrane adopts a unique support layer membrane technology, so that its tensile strength and compressive strength are much higher than that of ordinary hollow fiber membrane, the tensile strength of a single membrane wire is greater than 50KG, and it is vividly called “the membrane that cannot be stretched”.

- Good anti-pollution performance: The enhanced composite PVDF hollow fiber membrane has excellent anti-pollution performance due to its ultra-smooth membrane surface characteristics and unique charge performance, which are achieved by using PVDF alloy formulation as its filter layer.

- Ultra-high flux: The enhanced composite PVDF hollow fiber membrane adopts relatively independent special support layer technology and PVDF alloy membrane filtration layer technology, resulting in high porosity of the filtration layer. The produced membrane not only has high strength, but also good flux.

- Good retention performance: The enhanced composite PVDF hollow fiber membrane uses PVDF alloy membrane as the filter layer, and its special internal and external dense double-layer structure makes it have superior retention performance.

- Good cleaning flux recovery: The enhanced composite PVDF hollow fiber membrane uses PVDF alloy membrane as the filter layer. Its special inner and outer dense double-layer structure makes the pollutants only stay on the outer surface of the membrane and will not enter the mesh pores of the membrane, thus it is very easy to clean and has good cleaning flux recovery.

- The composite PVDF membrane has good chemical stability, acid and alkali resistance, bacterial corrosion resistance and good oxidation resistance.

- Product application fields:

- Pre-treatment of purified water and pure water: sterilization and turbidity purification of tap water, groundwater, surface water (mountain spring water, reservoir water); pre-treatment of pure water equipment such as reverse osmosis and nanofiltration.

- Separation and concentration of biopharmaceutical and food and beverage: separation and concentration of plant extracts, antibiotics, proteins, amino acids, enzyme preparations, milk, soy milk, yellow wine, soy sauce, vinegar and so on.

- Recovery and concentration of special liquids: recovery and concentration of electrophoretic paint, electroplating wastewater, waste alkali liquid, waste acid liquid, waste solvent and so on.

- The performance of polyvinylidene fluoride (PVDF) alloy hollow fiber membrane is superior.The membrane module adopts polyvinylidene fluoride (PVDF) alloy hollow fiber membrane, which has the characteristics of high strength, good anti-pollution, good oxidation resistance, good retention performance, large water production flux, good hydrophilicity and good cleaning flux recovery.

- The external pressure structure makes the cleaning more convenient and thorough. The membrane module adopts the external pressure structure which is not easy to block, and has better water distribution, larger filtration area and higher pollutant interception capacity, so that the cleaning of the module is more convenient and thorough.

- Full Flow Filtration, low energy consumption, and low operating costs. The membrane modules primarily operate in full flow filtration mode, which results in lower operating pressure and energy consumption compared to cross-flow filtration, thus leading to even lower operating costs. However, the modules can also be easily converted to cross-flow filtration mode, allowing for the processing of water with poorer quality. Therefore, the specific operating mode should be determined based on the quality of the raw water.

- Constant Flow Method, Simple Operation. Membrane modules often operate in a constant flow mode, with the transmembrane pressure difference gradually increasing over time. At this point, flux recovery is achieved through regular backwashing, air washing, and chemical cleaning. Adding biocides to the backwash water can effectively control microbial proliferation within the membrane module, thoroughly removing contaminants from the membrane surface.

- High degree of automation and convenient management The membrane componentsare generally controlled by PLC for the whole process, which is convenient to manage.

- Main performance parameters of the product:

Model: UF 6040-PVDF-CO

| Performance | Initial flux (T/H) | 3.5-4.5 |

| Design water production (T/H) | 1.5-2.5 | |

| Design flux (L/m².h) | 80-160 | |

| Surface water pollution index (SDI)② | <2 | |

| Water turbidity③ | <0.2NTU | |

| SS removal rate | 99.99% | |

| Microorganisms, bacteria, pathogens | 99.99% | |

|

Specifications |

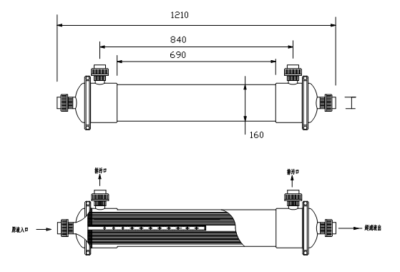

Component size (mm) | 160×12 00 |

| Type of membrane wire | External pressure hollow fiber | |

| Membrane material | Enhance PVDF membrane | |

| Inner/outer diameter of hollow fiber (mm) | 1. 0/ 2.4 | |

| Retention molecular weight (Daltons) | 100,000 | |

| Effective membrane area (m²) | 20 | |

| Number of hollow fibers | 2,700 | |

| Shell material | UPVC | |

| Sealing material | epoxy resin | |

| Recommended Operating Conditions | Recommended transmembrane pressure difference (TMP) (MPa) | 0.15-0.20 |

| Maximum inlet pressure (MPa) | 0.3 5 | |

| Maximum membrane pressure difference (MPa) | 0.2 5 | |

| Maximum anti-wash membrane pressure difference (MPa) | 0. 20 | |

| end-use temperature | 5-45℃ | |

| PH tolerance range | 1-1 2 | |

| Chemical cleaning chlorine concentration is tolerable | 5 00PPm | |

| run mode | Full or crossflow filtration | |

| Typical Process Conditions | Anti-wash flow (L/m².h) | 1.5-2 times water flow |

| Anti-wash pressure (TMP) (MPa) | 1.5 times the working pressure | |

| Anti-wash time | 20-180 seconds | |

| Anti-wash cycle | 20-60 minutes | |

| Shunchong flow (L/m².h) | 1.5-2 times water flow | |

| Shunchong time | 10-30 seconds | |

| Shun Chong cycle | 10-60 minutes | |

| Chemical cleaning cycle | 6 0-180 days | |

| Chemical cleaning time | 15-120 minutes | |

| Chemical cleaning agents | Citric acid, NaOH/NaClO, H2O2 |

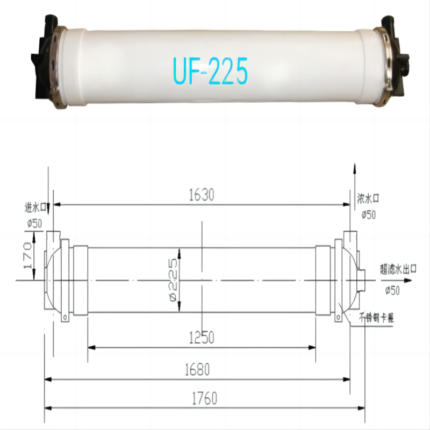

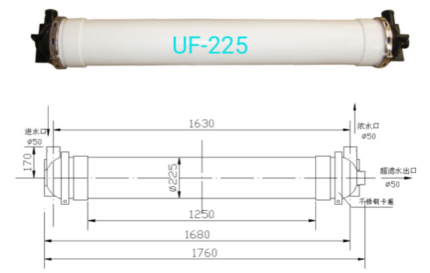

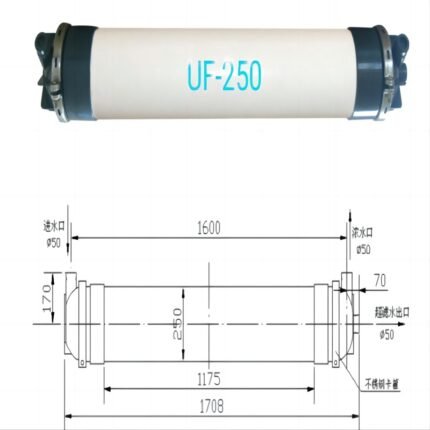

Ⅳ. Product size: Model: UF 4040-PVDF-CO

| Live joint A | Component outer diameter B | Side mouth distance C | Overall length D |

| DN 25 | 90mm | 921 mm | 1128 mm |

UF6040-PVDF Enhanced Hollow Fiber Membrane

MBR Membrane

MBR Membrane Reverse Osmosis Membrane

Reverse Osmosis Membrane Residential Ro Membrane

Residential Ro Membrane UF Membrane

UF Membrane Water Treatment Plant

Water Treatment Plant Residential Ro Machine

Residential Ro Machine Brackish Ro System

Brackish Ro System Sea water system/SW RO plant

Sea water system/SW RO plant Membrane Cleaning System(CIP)

Membrane Cleaning System(CIP) Consumables Accessories

Consumables Accessories