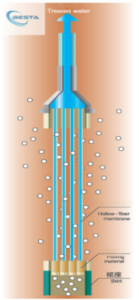

The BMUF100-PureX160 membrane module is made of PVDF hollow fiber ultrafiltration membrane prepared by advanced thermal-induced phase separation (TIPS) method. It features a homogeneous sponge-like structure, offering high strength, high flux, resistance to fouling, and recoverability. The immersed membrane module skid integrates aeration and permeate pipelines into one, fully submerged in the filtered water. The visualized membrane operating environment contributes to stable membrane operation.

The immersed system is highly integrated, with easy module installation, a rational skid design, uniform aeration, high permeate flow, and a compact footprint. Hydrophilic treatment results in low energy consumption for low-pressure suction. The external frame-type membrane housing effectively protects the fibers from impact. The open-type membrane housing design enhances fouling resistance and ease of cleaning, ensuring long-term stable operation of the membrane system.

Product Features and Advantages:

- Long Service Life:High tensile strength with dual-layer encapsulation technology.

- Cost Savings:Low pretreatment requirements, large water flux, high water recovery rate, hydrophilic treatment, low-pressure suction, and low energy consumption.

- Excellent Water Quality:Homogeneous sponge-like structure, resistant to fiber breakage.

- Highly Integrated:Minimal space requirement with a high-density membrane system design.

- Long Cleaning Cycle:Cleaning pH range of 2-11, resistant to up to 5000mg/L of sodium hypochlorite for cleaning.

- Easy Installation:Integrated aeration and water collection, simplified piping, and easy assembly and disassembly with a hanging design.

Specifications

| MBR module | Type | BMUF100-PureX160 |

| Material | PVDF | |

| Membrane area(m2) | 35 | |

| Pore size (um) | 0.1 | |

| Fiber ID/OD (mm) | 0.7/1.3 | |

| Membrane Fabrication Method | TIPS | |

| Module size | Dimension (mm) | 160*1800 |

| Connection size | M65*3 Threaded connection | |

| Material | Housing Material | U-PVC//ABS |

Operation conditions

| Conditions | Temperature range | 1-45℃ |

| Continuous pH range | 2-11 | |

| Operation flux (LMH) | 20-60 | |

| Backwash flux (LMH) | 30-120 | |

| Air flow (Nm3/h,piece ) | 6-12 | |

| Chemical cleaning pH range | 2-14 | |

| Operating TMPA | -0.03 | |

| Max. TMPA | -0.08 | |

| Max. Backwash pressure (Mpa) | 0.25 | |

| Product capacity | Permeate Turbidity (NTU) | ≤0.2 |

| Production and water pollution index (SDI15) | ≤3.0 |

Application

- Sewage

- Food industry

- Electronic industry

- Chemical industry

- Landfill leachate

MBR Membrane

MBR Membrane Reverse Osmosis Membrane

Reverse Osmosis Membrane Residential Ro Membrane

Residential Ro Membrane UF Membrane

UF Membrane Water Treatment Plant

Water Treatment Plant Residential Ro Machine

Residential Ro Machine Brackish Ro System

Brackish Ro System Sea water system/SW RO plant

Sea water system/SW RO plant Membrane Cleaning System(CIP)

Membrane Cleaning System(CIP) Consumables Accessories

Consumables Accessories