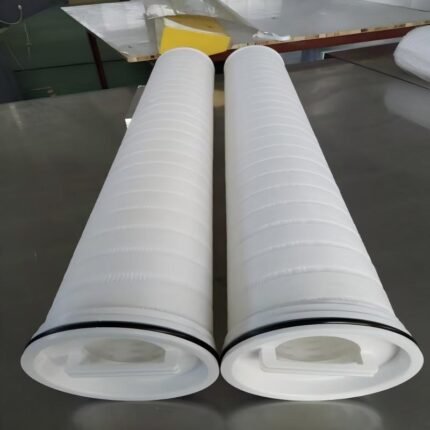

The BMUF100-10048/10072 ultrafiltration cartridge is engineered with advanced semi-permeable polyethersulfone material, offering exceptional filtration performance and durability. Its hollow fiber construction and proprietary potting compound ensure high efficiency and consistent operation. The cartridge delivers a large membrane area of 554 ft² (51.5 m²), supporting a production range of 15.4 to 32.2 GPM (3.5 to 7.4 m³/hr), making it ideal for demanding filtration requirements.

The BMUF100-10048/10072 ultrafiltration cartridge can operate under varying pH levels (1.5-13), excellent chlorine resistance during cleaning, and compatibility with diverse operating conditions. Designed for long-lasting performance, it is widely used in municipal water treatment, industrial process water, food and beverage production, and wastewater recycling.

With its robust PVC housing and compliance with NSF/ANSI certifications, tThe BMUF100-10048/10072 ensures reliable, safe, and cost-effective ultrafiltration solutions across a range of applications.

Product Introduction

| Product Specification | Model | BMUF100-10048 | BMUF100-10072 |

| Fiber Diameter(mm/inch) | 0.9/0.035 | 0.9/0.035 | |

| Membrane Area((㎡/ft²) | 51.5/554 | 80.9/871 | |

| Typical Production Range(m³hr/gpm) | 3.5-7.4/15.4-32.2 | 5.5-11.6/24.2-51.4 | |

| Diameter(mm/inch) | 273/10.75 | 273/10.75 | |

| Length(mm/inch) | 1219/48 | 1829/72 | |

|

Product description |

Membrane Chemistry | Proprietary Semi-Permeable Polyethersulfone | Proprietary Semi-Permeable Polyethersulfone |

| Molecular Weight Cutoff | 100000 | 100000 | |

| Housing Shell | PVC | PVC | |

| Permeat Collection Tube | PVC | PVC | |

| Fiber Support Netting | Polypropylene/Polyethylene | Polypropylene/Polyethylene | |

| Potting Material | Proprietary Compound | Proprietary Compound | |

| Membrane Construction | Hollow Fiber | Hollow Fiber | |

| Storage Solution | Glycerin/Water | Glycerin/Water | |

| Operating& Design information | Maximum Pressure(water) | 45psi(3.0bar) | 45psi(3.0bar) |

| Temperature Range | 0℃-40℃(32℉-104℉) | 0℃-40℃(32℉-104℉) | |

| Maximum production Transmembrane Pressure | 30psi(2.1bra) | 30psi(2.1bra) | |

| Maximum Backflush Transmembrane Pressure | 25psi(1.7bar) | 25psi(1.7bar) | |

| ph Range | 1.5-13 | 1.5-13 | |

| Maximum Total Chlorine@25℃(77℉) | 500ppm@pH>10 | 500ppm@pH>10 | |

| Typical Cleaning Total Chlorine@25℃(77℉) | 200ppm@pH>10 | 200ppm@pH>10 | |

| Maximum Backflush Total Chlorine@25℃(77℉) | 50ppm@pH>9 | 50ppm@pH>9 |

Cartridge Assembly And Components

| Item | Description | Required for Single Permeate Removal | Required for Dual Permeate Removal | |

| 1 | 10″HF Cartridge | 1 each | 1 each | |

| 2 | 10″HF Couoling | 2 each | 2 each | |

| 3 | 10″HF Face Seal | 2 each | 2 each | |

| 4 | 10″HF K-Ring | 2 each | 2 each | |

| 5 | Permeate O-Rings | 4 each | 4 each | |

| 6 | 10″Plastic HF End Cap W Port | 1 each | 2 each | |

| 7 | 10″Plastic HF End Cap W/O Port | 1 each | 0 each | |

| 8 | 10″HF End Cartridge Support | 2 each | 2 each | |

| 9 | 10″HF Cartridge Support Hardware | 2 each | 2 each | |

| 10 | 2″Groove-End Coupling | 3 each | 4 each |

CARTRIDGESTORAGECONDITIONS:

New cartridges are packaged in a glycerin/water solution. The glycerin/water solution should be removed from new cartridges before their initial use with a water rinse followed by a caustic wash followed by caustic/chlorine wash.Prior to installation, cartridges should be stored in their original packaging under the following conditions:

- Indoors, out of direct sunlight.

- Temperatures between 50-85°F(10-30°C)

- Relative humidity below 70%.

- In a horizontal position.

- Itis best to use new cartridges within one year of shipment.

Used cartridges should be cleaned,rinsed and impregnated before storage with one of the following solutions:

- Glycerin@80-100%(best)

- Phosphoric acid@pH2-3

- Benzoic acid or sodium benzoate @1,000 ppm

- Sodium bisulfite or sodium metabisulfte@1005000ppm

Cartridges stored in sodium bisulfite or sodium metabisulfite should be flushed with clean water and impregnated with fresh solution at six-month intervals. Once impregnated the cartridges should be left on the system with all valves closed or removed from the system and sealed in plastic bags. Storage conditions described above for new cartridges should also be used for storage of used cartridges. Cartridges must be drained, rinsed, and cleaned after storage per the pre-startup cleaning instruction sheet packed with each cartridge shipment.

MBR Membrane

MBR Membrane Reverse Osmosis Membrane

Reverse Osmosis Membrane Residential Ro Membrane

Residential Ro Membrane UF Membrane

UF Membrane Water Treatment Plant

Water Treatment Plant Residential Ro Machine

Residential Ro Machine Brackish Ro System

Brackish Ro System Sea water system/SW RO plant

Sea water system/SW RO plant Membrane Cleaning System(CIP)

Membrane Cleaning System(CIP) Consumables Accessories

Consumables Accessories