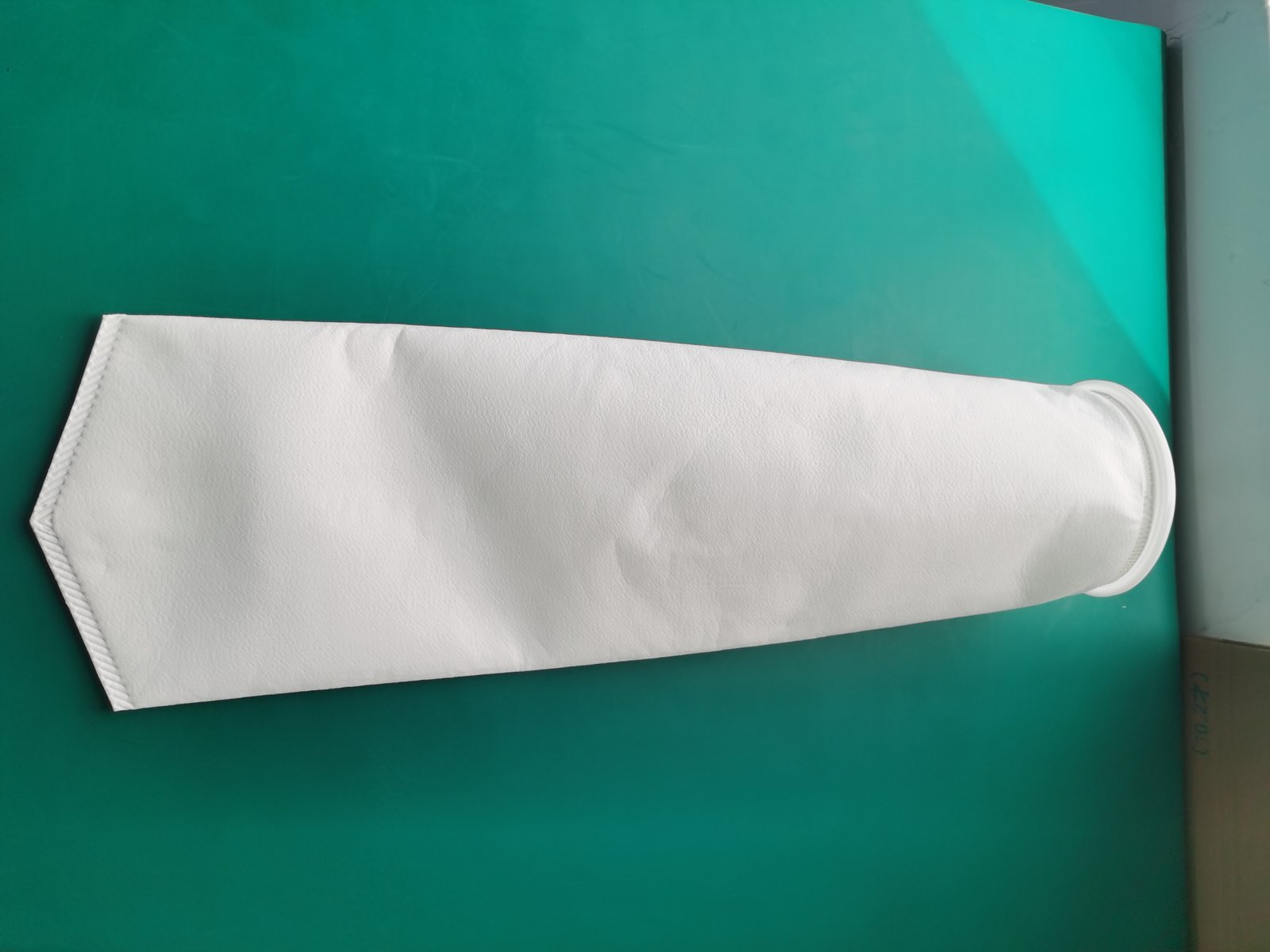

Estabilidad química fuerte–Bolsa de filtro de educación física

Bolsas de filtro de PE, con su excelente estabilidad química, resistencia a la corrosión, y rentabilidad, Son muy favorecidos en campos como el tratamiento de agua., comida y bebida, químico, y las industrias farmacéuticas.

Material:educación física

Especificación:01/02/03/04/05

Exactitud:0.5-500µm

Temperatura:≤120 ℃

Proceso de fabricación:Fusión en caliente / Puntadas

Forma de brida del anillo:Interior rodado / Afuera rodó / Brida plana / Anillo de acero

Forma inferior:Fondo puntiagudo, Fondo redondo, Fondo arqueado, Fondo plano

| Especificaciones de la bolsa de filtro | ||||

| Especificación | Tamaño mm(pulgada) | Caudal (m³/h) | Área de filtración (m²) | Capacidad (L) |

| 01# | 180*430(7″*17) | 20 | 0.24 | 8 |

| 02# | 180*810(7″*32) | 40 | 0.48 | 17 |

| 03# | 105*230(4″*9″) | 6 | 0.08 | 1.3 |

| 04# | 105*380(4″*15″) | 12 | 0.16 | 2.6 |

| 05# | 150*560(6″*22″) | 20 | 0.24 | 8 |

| Nota: El caudal se mide bajo 1 cajero automático, agua pura a una viscosidad de 1.25 ° C, Representando la velocidad de flujo por hora por bolsa de filtro. | ||||

Fabricado con materiales de fibra de alta pureza mediante soldadura o costura., la estructura de la tela está suelta, lo que aumenta significativamente la capacidad de retener impurezas. Este material de fibra utiliza un modo de filtración compuesto., capturar eficazmente partículas sólidas y blandas. Las partículas de impureza del líquido quedan atrapadas en la superficie de la tela., mientras que las impurezas más finas son capturadas en las capas más profundas del material. Esto asegura que la bolsa de filtro no se romperá debido al aumento de presión durante el uso., proporcionando una mayor eficiencia de filtración. La superficie de la tela de la bolsa filtrante se somete a un tratamiento térmico a alta temperatura., aplicando tecnología de sinterización instantánea o calandrado, que evita eficazmente que las fibras de la superficie de la tela se desprendan debido al impacto del líquido a alta velocidad durante la filtración.

Membrana MBR

Membrana MBR Membrana de ósmosis inversa

Membrana de ósmosis inversa Membrana RO residencial

Membrana RO residencial Membrana UF

Membrana UF Planta de tratamiento de agua

Planta de tratamiento de agua Máquina residencial RO

Máquina residencial RO Sistema RO salobre

Sistema RO salobre Sistema de agua de mar/planta SW ro

Sistema de agua de mar/planta SW ro Filtro de bolsa

Filtro de bolsa Filtro de cartucho

Filtro de cartucho Sistema de filtración de agua comercial

Sistema de filtración de agua comercial Sistema de limpieza de membrana(Titubear)

Sistema de limpieza de membrana(Titubear) Accesorios de consumo

Accesorios de consumo