Recipientes a presión compuestos de FRP

Our FRP composite pressure vessels are made with a high-quality HDPE liner and reinforced with epoxy resin and fiberglass. They are lightweight, durable, and corrosion-resistant, with working pressures up to 150 PSI. Certified by NSF, ISO9001, ISO14001, and CE, these vessels are ideal for water softening, filtración, and reverse osmosis systems.

Descripción del Producto

Nuestro FRP (Fiberglass Reinforced Plastic) Composite Pressure Vessels are designed for a wide range of water treatment applications, including industrial, civil, and commercial systems. Manufactured with a high-quality HDPE liner and reinforced with epoxy resin and glass fiber winding, these tanks provide exceptional strength, resistencia a la corrosión, and long service life.

They are lightweight, durable, and easy to install, making them the ideal choice for filtration, softening, and reverse osmosis pre-treatment processes.

Características clave

-

High Performance: Working pressure of 125 PSI or 150 PSI.

-

Construcción duradera: HDPE inner liner with epoxy resin + glass fiber winding for maximum strength.

-

Certified Quality: NSF certification, ISO9001 quality management certification, ISO14001 environmental system certification, CE certification.

-

Reliable & Safe: Passed more than 100,000 fatigue tests, 4 times burst pressure test, y 1.2 times water retention test.

-

Flexible Applications: Suitable for industrial, residential, and commercial water treatment systems.

-

Rango de temperatura: 1°C – 49°C (34°F – 120°F).

-

Presupuesto: Diameters from 150 mm to 2000 mm, sizes from 6 inches to 80 pulgadas.

Ventajas

-

Corrosion-resistant and non-toxic materials ensure water safety.

-

Easy installation with top and bottom flange options (4″ and 6″ flanges available).

-

Lightweight yet strong structure for convenient handling.

-

Long service life with stable pressure performance.

Aplicaciones típicas

-

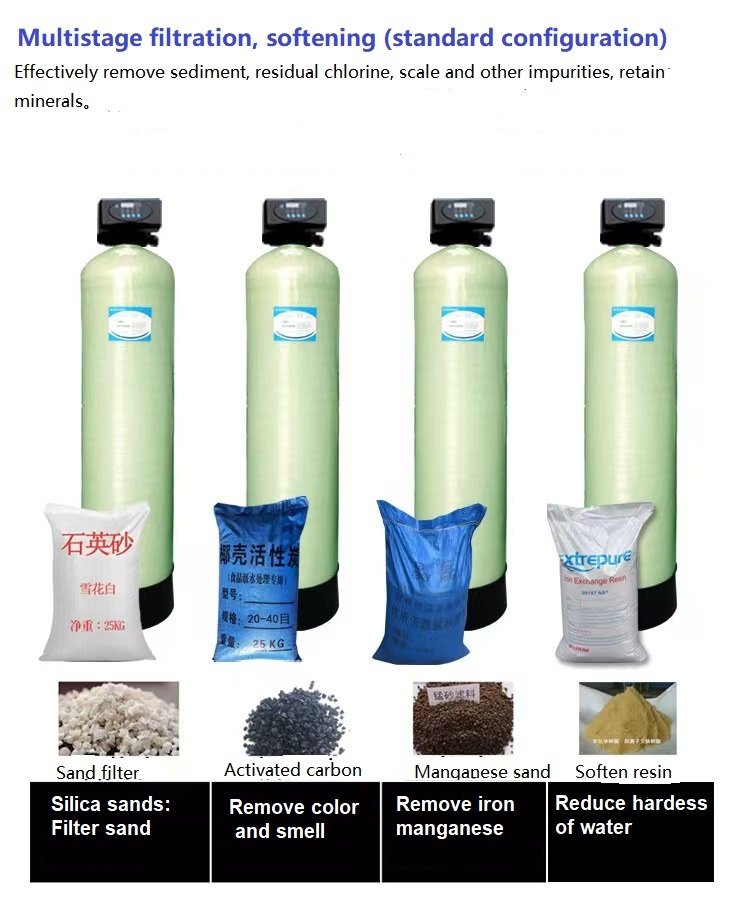

Water softening systems

-

Sand and multimedia filters

-

Activated carbon filters

-

Reverse osmosis pre-treatment

Membrana MBR

Membrana MBR Membrana de ósmosis inversa

Membrana de ósmosis inversa Membrana RO residencial

Membrana RO residencial Membrana UF

Membrana UF Planta de tratamiento de agua

Planta de tratamiento de agua Máquina residencial RO

Máquina residencial RO Sistema RO salobre

Sistema RO salobre Sistema de agua de mar/planta SW ro

Sistema de agua de mar/planta SW ro Filtro de bolsa

Filtro de bolsa Filtro de cartucho

Filtro de cartucho Sistema de filtración de agua comercial

Sistema de filtración de agua comercial Sistema de limpieza de membrana(Titubear)

Sistema de limpieza de membrana(Titubear) Accesorios de consumo

Accesorios de consumo