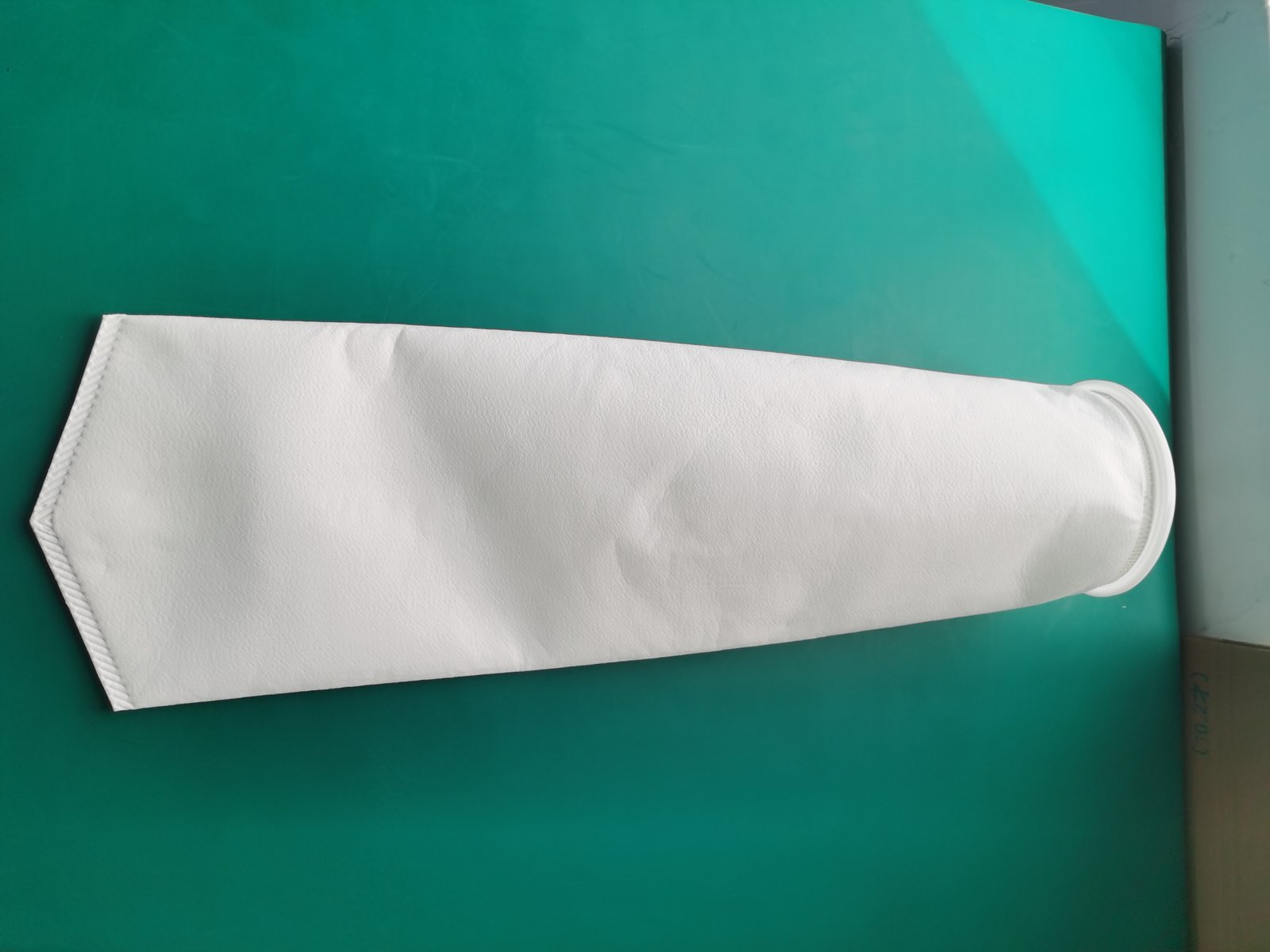

Strong Chemical Stability–PE Filter Bag

PE Filter Bags, with their excellent chemical stability, corrosion resistance, and cost-effectiveness, are highly favored in fields such as water treatment, food and beverage, chemical, and pharmaceutical industries.

Material:PE

Specification:01/02/03/04/05

Accuracy:0.5-500µm

Temperature:≤120℃

Manufacturing process:Hot melt / Stitching

Ring flange shape:Inside rolled / Outside rolled / Flat flange / Steel ring

Bottom shape:Pointed bottom, Round bottom, Arched bottom, Flat bottom

| Filter bag specifications | ||||

| Specification | Size mm(inch) | Flow Rate (m³/h) | Filtration Area (m²) | Capacity (L) |

| 01# | 180*430(7″*17) | 20 | 0.24 | 8 |

| 02# | 180*810(7″*32) | 40 | 0.48 | 17 |

| 03# | 105*230(4″*9″) | 6 | 0.08 | 1.3 |

| 04# | 105*380(4″*15″) | 12 | 0.16 | 2.6 |

| 05# | 150*560(6″*22″) | 20 | 0.24 | 8 |

| Note: The flow rate is measured under 1 atm, pure water at a viscosity of 1,25°C, representing the hourly flow rate per filter bag. | ||||

Made from high-purity fiber materials through welding or stitching, the fabric structure is loose, which significantly increases the capacity to hold impurities. This fiber material uses a composite filtration mode, effectively capturing solid and soft particles. The particulate impurities in the liquid are trapped on the surface of the fabric, while finer impurities are captured in the deeper layers of the material. This ensures that the filter bag will not break due to increased pressure during use, providing higher filtration efficiency. The surface of the filter bag fabric undergoes high-temperature heat treatment, applying instant sintering technology or calendering, which effectively prevents the fibers on the fabric’s surface from shedding due to high-speed liquid impact during filtration.

MBR Membrane

MBR Membrane Reverse Osmosis Membrane

Reverse Osmosis Membrane Residential Ro Membrane

Residential Ro Membrane UF Membrane

UF Membrane Water Treatment Plant

Water Treatment Plant Residential Ro Machine

Residential Ro Machine Brackish Ro System

Brackish Ro System Sea water system/SW RO plant

Sea water system/SW RO plant Bag Filter

Bag Filter Cartridge Filter

Cartridge Filter Commercial Water Filtration System

Commercial Water Filtration System Membrane Cleaning System(CIP)

Membrane Cleaning System(CIP) Consumables Accessories

Consumables Accessories